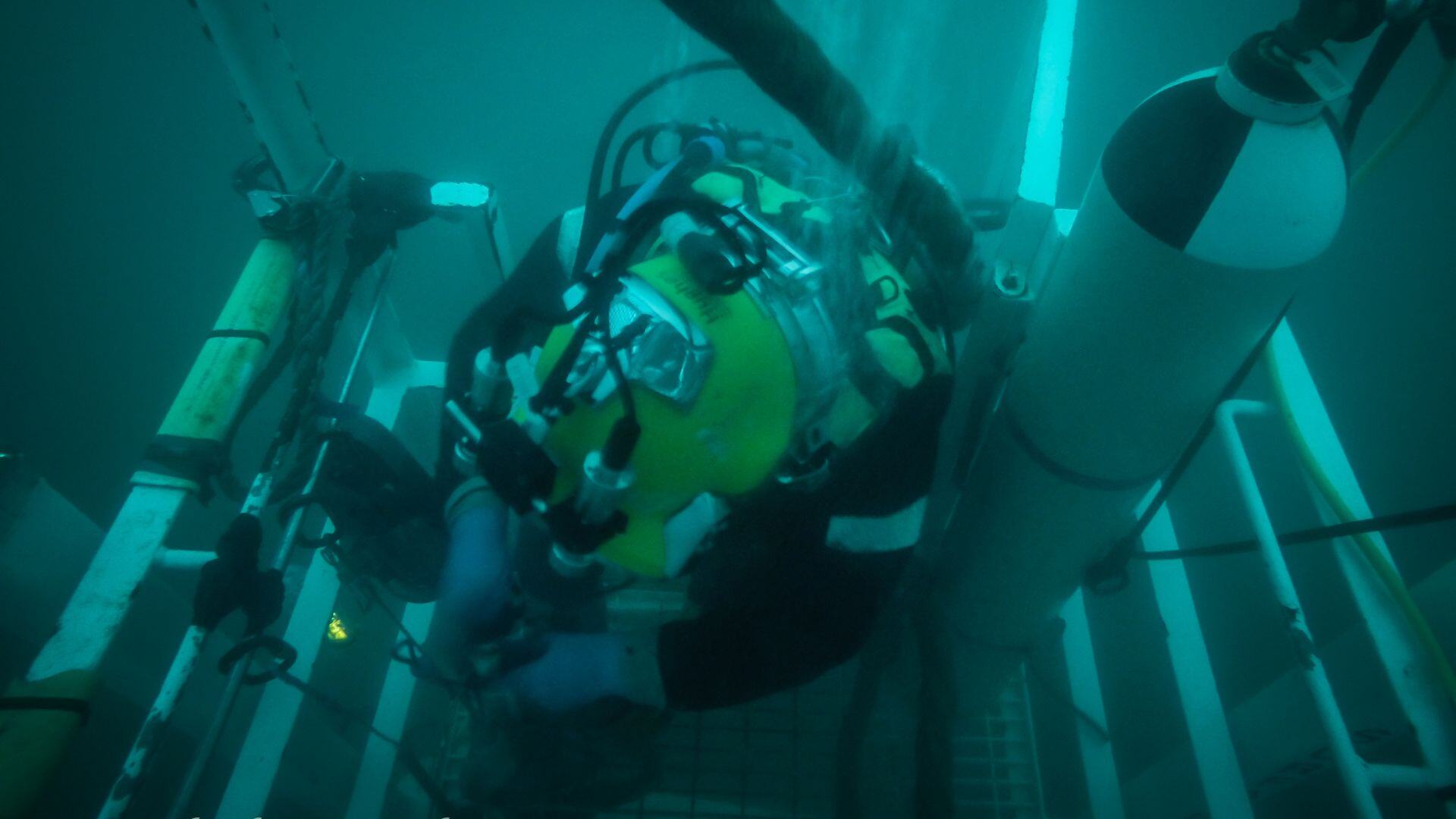

Subsea IRM (diver)

Provision of cutting-edge, modular, air-diving spreads and experienced, time-served and competent divers.

Overview

Our extensive experience provides our team with unrivalled subsea knowledge and expertise; this, combined with the latest industry-leading technology, allows our commercial diving division to provide reliable services for the duration of our customers' subsea projects.

Our diving activities are supported by our in-house commercial diving systems; we own and operate various cutting-edge, modular, air-diving spreads. These allow us to execute complex subsea tasks up to 50 metres below the surface.

Our team consists of 3.1u and 3.2u divers, 3.4u inspection coordinators and we offer a range of inspection reporting software packages such as COABIS, Digital Edge, Integrity Elements and Apollo KnowHow.

We are fully accredited members of the Association of Diving Contractors (ADC) and the International Marine Contractors Association (IMCA).

Diving equipment

Diving control container

Our Dive Control Container is the hub from which the ongoing diving operations are managed. Our dive controls are equipped with 3-diver nitrox panels, diver comms, diver depth data logging, digital video recording and monitoring (including black box recording). All included and associated equipment meets the requirements of IMCA D023. Our 20ft container systems include an inspection control office with additional video recording and overlay equipment.

Our dive control containers can include various accessories together with safety equipment, diver equipment storage areas for umbilicals, communications systems and much more.

Diving control container

Our Dive Control Container is the hub from which the ongoing diving operations are managed. Our dive controls are equipped with 3-diver nitrox panels, diver comms, diver depth data logging, digital video recording and monitoring (including black box recording). All included and associated equipment meets the requirements of IMCA D023. Our 20ft container systems include an inspection control office with additional video recording and overlay equipment.

Our dive control containers can include various accessories together with safety equipment, diver equipment storage areas for umbilicals, communications systems and much more.

Our Dive Control Container is the hub from which the ongoing diving operations are managed. Our dive controls are equipped with 3-diver nitrox panels, diver comms, diver depth data logging, digital video recording and monitoring (including black box recording). All included and associated equipment meets the requirements of IMCA D023. Our 20ft container systems include an inspection control office with additional video recording and overlay equipment.

Our dive control containers can include various accessories together with safety equipment, diver equipment storage areas for umbilicals, communications systems and much more.

Diving machinery container

Our 2.99 x 2.46m bespoke machinery / compressor diving containers can include various equipment. Including HP Compressor, LP Tooling Compressor and a Haskel pump. Each air or nitrox dive spread is mobilised with a machinery or compressor container, which includes plant and equipment needed to support the operation – hot water system, HP compressor, LP compressor, hydraulic power pack for small tools etc.

Diving machinery container

Our 2.99 x 2.46m bespoke machinery / compressor diving containers can include various equipment. Including HP Compressor, LP Tooling Compressor and a Haskel pump. Each air or nitrox dive spread is mobilised with a machinery or compressor container, which includes plant and equipment needed to support the operation – hot water system, HP compressor, LP compressor, hydraulic power pack for small tools etc.

Our 2.99 x 2.46m bespoke machinery / compressor diving containers can include various equipment. Including HP Compressor, LP Tooling Compressor and a Haskel pump. Each air or nitrox dive spread is mobilised with a machinery or compressor container, which includes plant and equipment needed to support the operation – hot water system, HP compressor, LP compressor, hydraulic power pack for small tools etc.

Deck compression container

Built to the highest quality, each offshore dive spread includes a 2-man, 2-compartment, containerised deck decompression chamber (DDC). The DDC is used to support emergency and therapeutic decompression and/ or planned surface decompression in a compact and efficient package. This is achieved by combining the decompression chamber hull, its control system, emergency gas storage and support equipment into a single containerised unit.

Our decompression diving chamber containers are used as essential equipment for all types of subsea operations from dive support vessels to salvage and research vessels.

Deck compression container

Built to the highest quality, each offshore dive spread includes a 2-man, 2-compartment, containerised deck decompression chamber (DDC). The DDC is used to support emergency and therapeutic decompression and/ or planned surface decompression in a compact and efficient package. This is achieved by combining the decompression chamber hull, its control system, emergency gas storage and support equipment into a single containerised unit.

Our decompression diving chamber containers are used as essential equipment for all types of subsea operations from dive support vessels to salvage and research vessels.

Built to the highest quality, each offshore dive spread includes a 2-man, 2-compartment, containerised deck decompression chamber (DDC). The DDC is used to support emergency and therapeutic decompression and/ or planned surface decompression in a compact and efficient package. This is achieved by combining the decompression chamber hull, its control system, emergency gas storage and support equipment into a single containerised unit.

Our decompression diving chamber containers are used as essential equipment for all types of subsea operations from dive support vessels to salvage and research vessels.

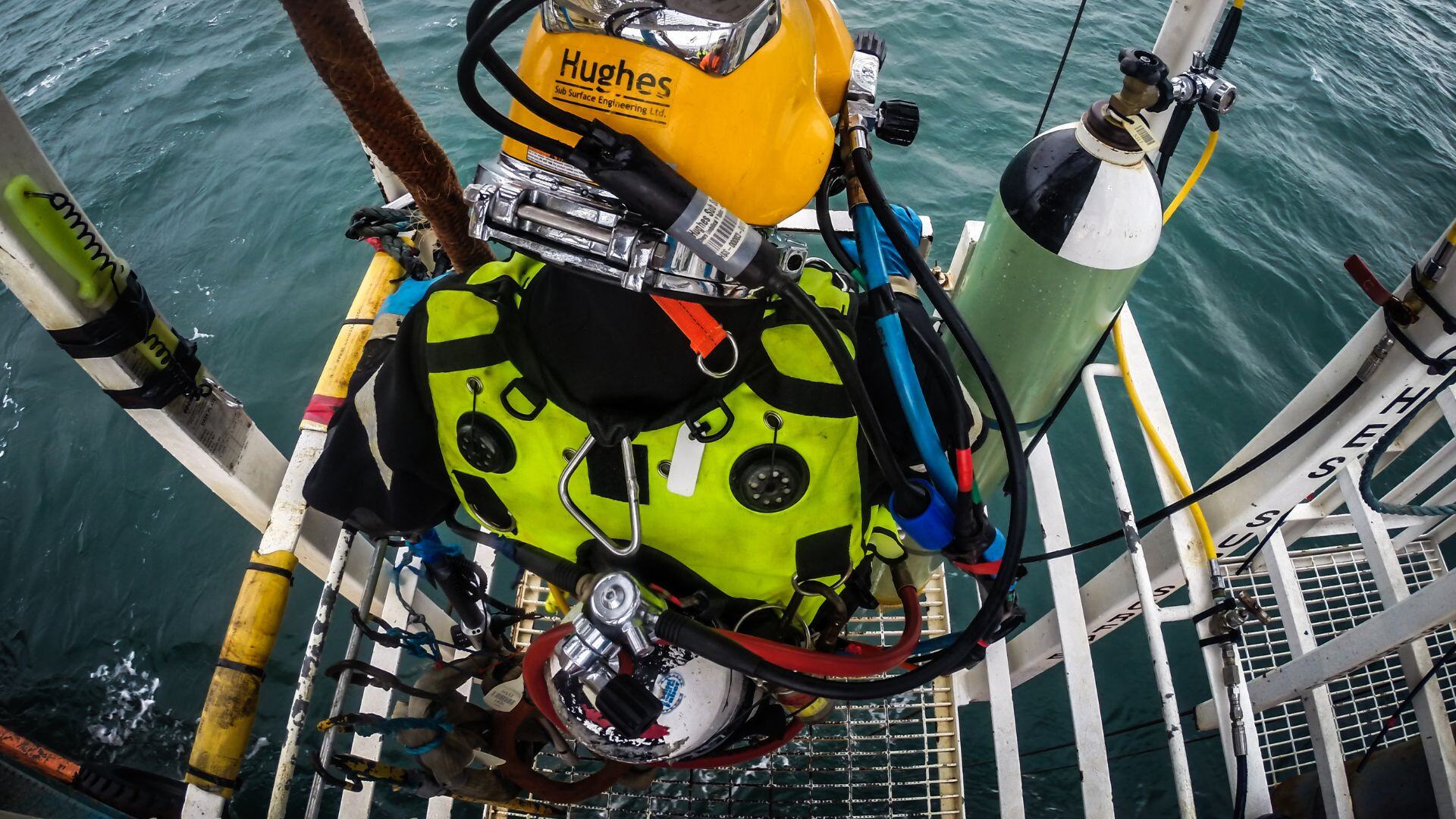

Launch recovery system (LARS)

Our two Diver Basket Launch and Recovery System (LARS) is designed to safely deploy/recover divers with equipment over-the-side from the dive control location (Dive Support Vessel (DSV), fixed installation, Jack-Up Barge (JUB) to the subsea dive site, down to a maximum working depth of 50m.

The LAR system typically consists of an A-frame complete with base. Including the HYDRA 650/0.65 series offshore man rider winch is based on the 1300 series frames and drums capacity. Furthermore, two hydraulic power packs situated on the A-frame skid directly beneath the winch and control station.

A diving 1.2m x 1.2m diving cage with overhead protection frame fitted with 1 x 50 litre 200 bar cylinder. A cylinder is included as part of the cage with 1st stage, 2 x DV’s, and 2 x ¼ inch pneumo hose for emergency use.

Launch recovery system (LARS)

Our two Diver Basket Launch and Recovery System (LARS) is designed to safely deploy/recover divers with equipment over-the-side from the dive control location (Dive Support Vessel (DSV), fixed installation, Jack-Up Barge (JUB) to the subsea dive site, down to a maximum working depth of 50m.

The LAR system typically consists of an A-frame complete with base. Including the HYDRA 650/0.65 series offshore man rider winch is based on the 1300 series frames and drums capacity. Furthermore, two hydraulic power packs situated on the A-frame skid directly beneath the winch and control station.

A diving 1.2m x 1.2m diving cage with overhead protection frame fitted with 1 x 50 litre 200 bar cylinder. A cylinder is included as part of the cage with 1st stage, 2 x DV’s, and 2 x ¼ inch pneumo hose for emergency use.

Our two Diver Basket Launch and Recovery System (LARS) is designed to safely deploy/recover divers with equipment over-the-side from the dive control location (Dive Support Vessel (DSV), fixed installation, Jack-Up Barge (JUB) to the subsea dive site, down to a maximum working depth of 50m.

The LAR system typically consists of an A-frame complete with base. Including the HYDRA 650/0.65 series offshore man rider winch is based on the 1300 series frames and drums capacity. Furthermore, two hydraulic power packs situated on the A-frame skid directly beneath the winch and control station.

A diving 1.2m x 1.2m diving cage with overhead protection frame fitted with 1 x 50 litre 200 bar cylinder. A cylinder is included as part of the cage with 1st stage, 2 x DV’s, and 2 x ¼ inch pneumo hose for emergency use.

IVM Hydro 300 - 3D photogrammetry

The IVM Hydro 300 is a versatile, compact, lightweight, and efficient solution for the inspection and 3D reconstruction of structures and seascapes with the benefits of project time and cost savings over traditional methodologies. Combined with the IVM SLAM technology, the IVM Hydro 300 delivers real-time imaging during survey/inspection operations.

By harnessing modern point-cloud and mesh technologies; post-processing provides a detailed and manoeuvrable 3D visualisation and true scaled results; with submillimetric accuracy. The generated 3D models are retrospectively measurable, allowing for detailed off-site visualisation, inspection, and comparison. This allows distribution with internal and external stakeholders for increased operational and management collaboration and decision making.

The IVM Hydro 300 is a multi-sector inspection tool which is deployable on Observation and Work Class Remote Operated Vehicles (ROVs) and can equally be operated by divers making it a versatile and cost-effective solution for multiple subsea inspections.

IVM Hydro 300 - 3D photogrammetry

The IVM Hydro 300 is a versatile, compact, lightweight, and efficient solution for the inspection and 3D reconstruction of structures and seascapes with the benefits of project time and cost savings over traditional methodologies. Combined with the IVM SLAM technology, the IVM Hydro 300 delivers real-time imaging during survey/inspection operations.

By harnessing modern point-cloud and mesh technologies; post-processing provides a detailed and manoeuvrable 3D visualisation and true scaled results; with submillimetric accuracy. The generated 3D models are retrospectively measurable, allowing for detailed off-site visualisation, inspection, and comparison. This allows distribution with internal and external stakeholders for increased operational and management collaboration and decision making.

The IVM Hydro 300 is a multi-sector inspection tool which is deployable on Observation and Work Class Remote Operated Vehicles (ROVs) and can equally be operated by divers making it a versatile and cost-effective solution for multiple subsea inspections.

The IVM Hydro 300 is a versatile, compact, lightweight, and efficient solution for the inspection and 3D reconstruction of structures and seascapes with the benefits of project time and cost savings over traditional methodologies. Combined with the IVM SLAM technology, the IVM Hydro 300 delivers real-time imaging during survey/inspection operations.

By harnessing modern point-cloud and mesh technologies; post-processing provides a detailed and manoeuvrable 3D visualisation and true scaled results; with submillimetric accuracy. The generated 3D models are retrospectively measurable, allowing for detailed off-site visualisation, inspection, and comparison. This allows distribution with internal and external stakeholders for increased operational and management collaboration and decision making.

The IVM Hydro 300 is a multi-sector inspection tool which is deployable on Observation and Work Class Remote Operated Vehicles (ROVs) and can equally be operated by divers making it a versatile and cost-effective solution for multiple subsea inspections.

.jpg?width=1460&height=830&name=).jpg)

Daughter craft capability

The dive craft is supported during offshore operations by support craft for supply and personnel transport. It is ideally suited for restricted area access around offshore vessels/platforms and MoDu where DSVs have limited access for maintenance/surveys. It is also ideal for harbourinspection and repair workscopes where access from quayside is restricted.