%20(1100%20x%20830%20px)%20(1200%20x%20675%20px)%20(3600%20x%201600%20px)%20(1460%20x%20830%20px)%20(3600%20x%201600%20px)%20(1360%20x%20705%20px)%20(3600%20x%201600%20px)%20(900%20x%20700%20px)%20(3600%20x%201600%20px)%20(1360%20x%20705%20px)%20(1360%20x%20%20(12).jpg?width=2000&name=Untitled%20(1460%20x%20830%20px)%20(1100%20x%20830%20px)%20(1200%20x%20675%20px)%20(3600%20x%201600%20px)%20(1460%20x%20830%20px)%20(3600%20x%201600%20px)%20(1360%20x%20705%20px)%20(3600%20x%201600%20px)%20(900%20x%20700%20px)%20(3600%20x%201600%20px)%20(1360%20x%20705%20px)%20(1360%20x%20%20(12).jpg)

Research and development

Pioneering new technology solutions for the offshore energy sector

Overview

Innovation is an important part of our operations. We are continuously looking for methods to perform our services better, simpler and more cost-effective for our client.

Our research and development department is committed to developing innovative tools and services that allow us to deliver safer and faster. In the field of subsea services in particular, our research and development capabilities have made great progress.

In recent years, we’ve developed various tailor-made tools for installing and inspecting subsea components, from idea and initial concept to implementation and offshore operation. Just another way in which we’re able to exceed our clients’ expectations and go the extra mile.

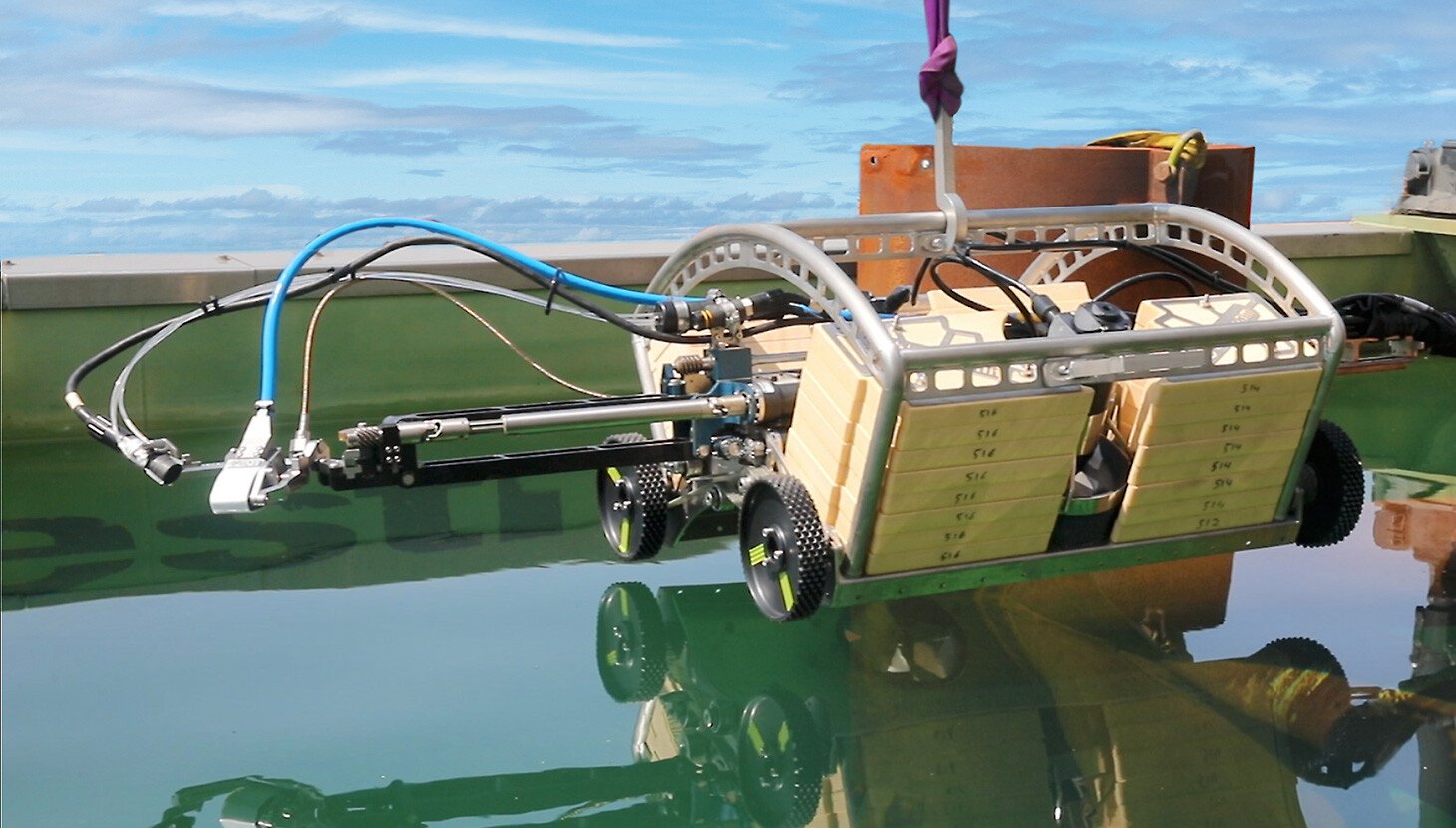

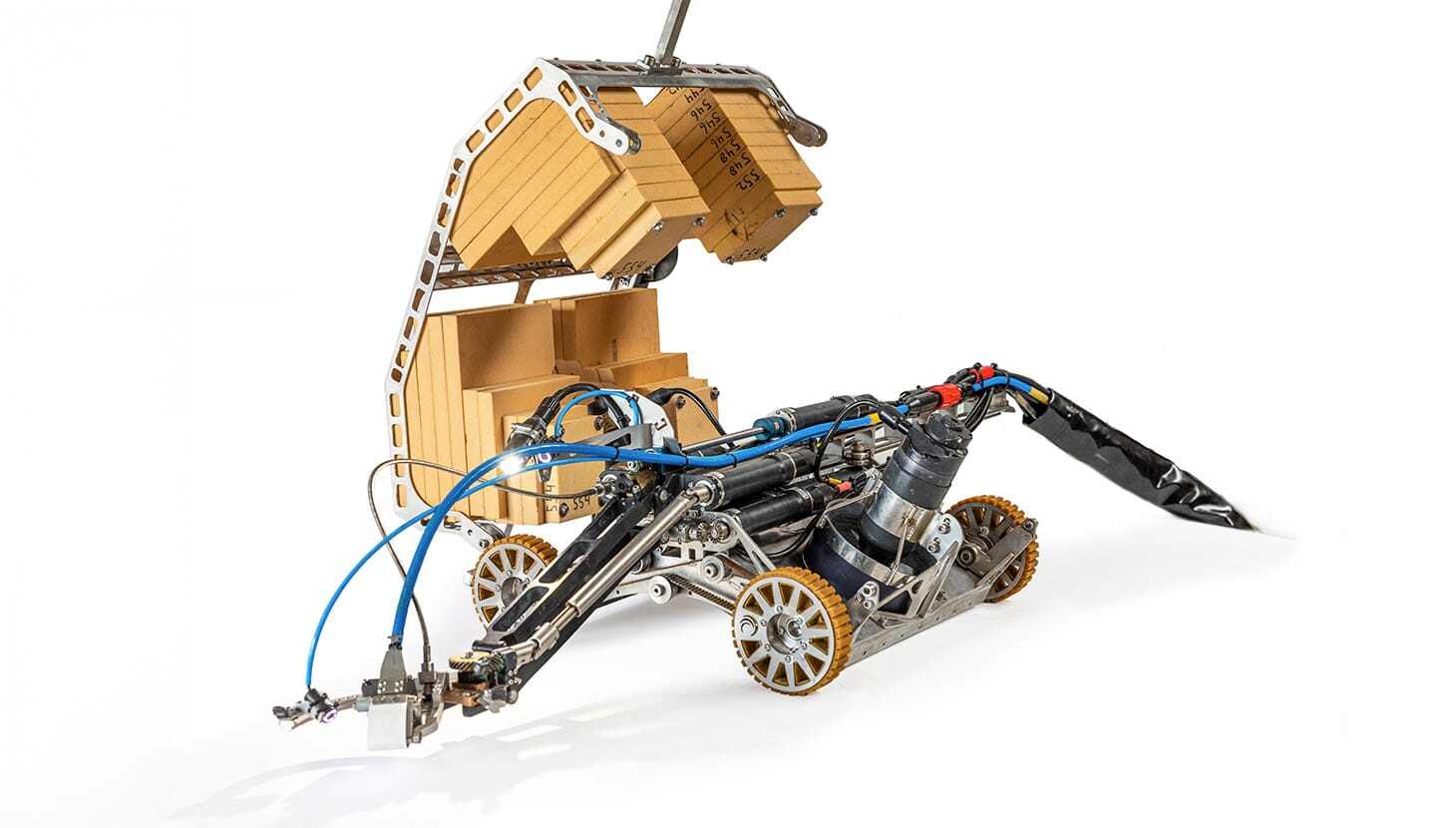

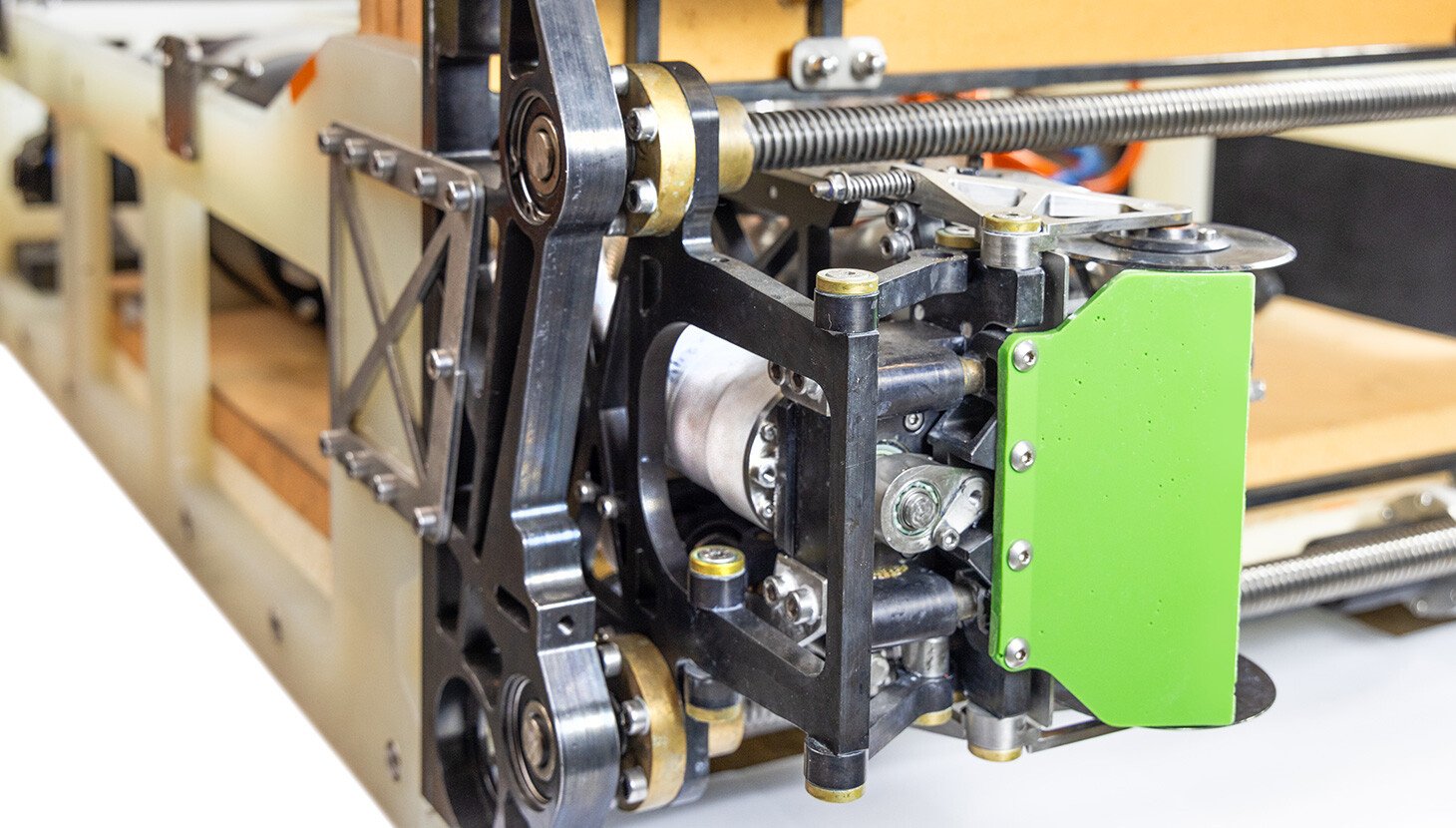

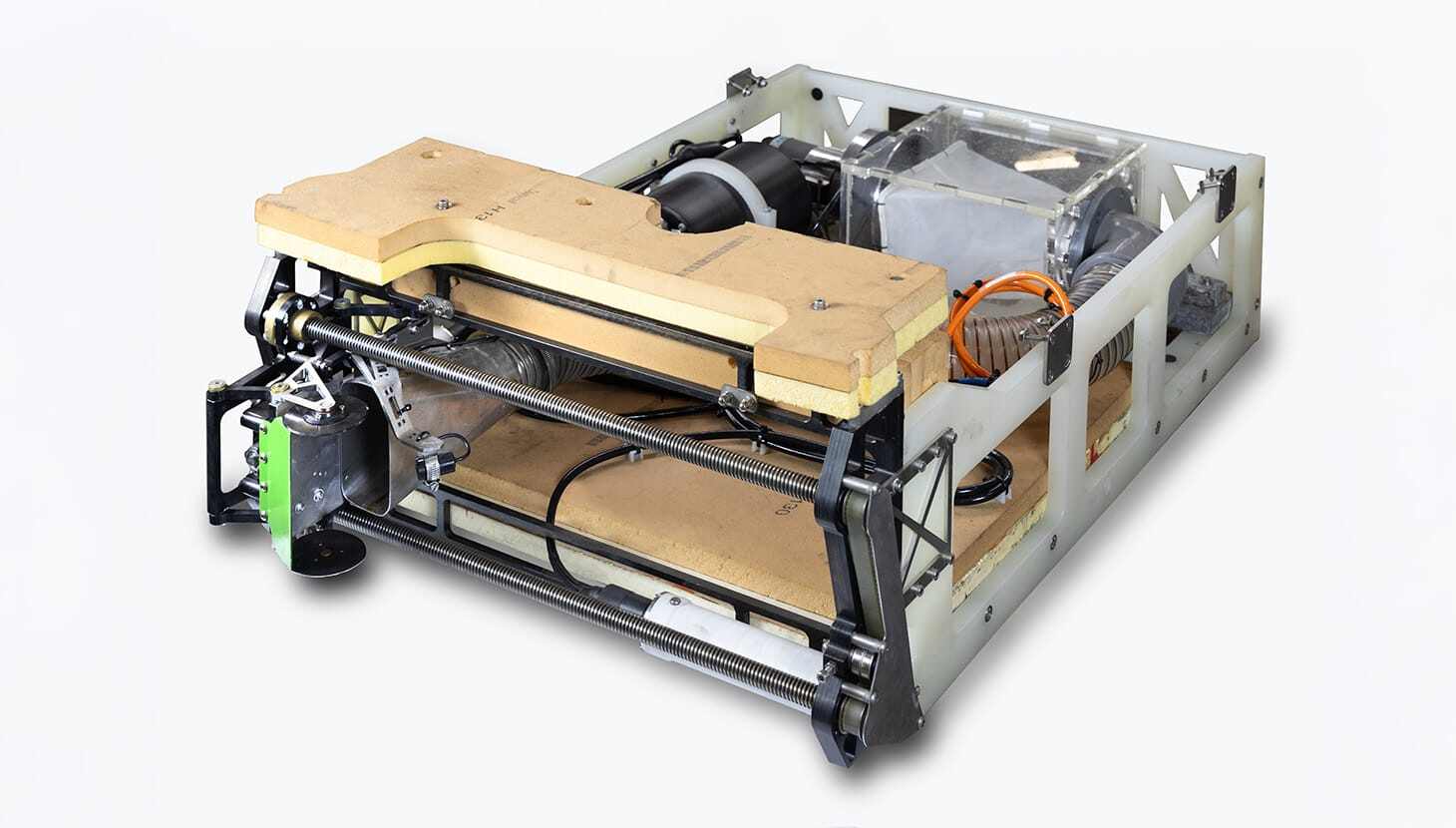

ICCP-Subsea Assembly Method

The ICCP-Subsea Assembly Method (ICCP-SAM) is an innovative tool for installing ICCP anodes from inside a monopile foundation, suitable for any water depth. With larger monopile foundations, corrosion protection becomes more difficult. Anodes must be placed deeper on the foundation, which can lead to costly external installations and risk of cable damage when pulling cables inside the monopile.

The ICCP-SAM, with an outer diameter under 800 mm, fits through standard hatches (850 x 950 mm) and holds the ICCP anode with hydraulic clamps. Thrusters enable precise control, and the anode is locked in place by a simple rotation and a 4-bolt fixation.

- No requirement for large, costly vessels

- No secondary steel structures are required

- Increased workability due to minimal current inside the foundation

- Cables remain protected inside the foundation

Gobiesox Inspection Tool

The Gobiesox is an advanced inspection tool deployed by an ROV that adheres to a member or surface using pressure and can perform inspections with a variety of sensors. With six degrees of freedom, the Gobiesox can perform inspections on a broad range of subsea locations.

The tool was designed to carry out Alternating Current Field Measurements (ACFM) on nodal joints, larger monopile welds or flat surfaces like vessel hulls or tanks, meaning it can be tailored to carry different sensors. The software’s intuitive control mechanism assists the operator in using the inspection probe, keeping track of its travel and location, by providing full feedback from all joints.

Marine Growth Sampling Tool

The Marine Growth Sampling Tool (MGST) was created to study underwater fauna on wind turbine foundations efficiently and safely.

The MGST was developed by Bluestream Offshore and Wageningen Marine Research to investigate underwater fauna on wind turbine foundations, addressing the high safety standards and costs associated with diving operations. First tested at the Hollandse Kust (South) wind farm, the MGST can be attached to a Remotely Operated Vehicle (ROV) to scrape marine life from turbine foundations. Initial tests collected 22 samples, revealing various marine species. Preserving turbine coatings was a key consideration, ensuring metal structures remain protected.

%20(1100%20x%20830%20px)%20(1200%20x%20675%20px)%20(3600%20x%201600%20px)%20(1460%20x%20830%20px)%20(3600%20x%201600%20px)%20(1360%20x%20705%20px)%20(3600%20x%201600%20px)%20(900%20x%20700%20px)%20(3600%20x%201600%20px)%20(1360%20x%20705%20px)%20(1360%20x%20%20(23).jpg?width=2000&name=Untitled%20(1460%20x%20830%20px)%20(1100%20x%20830%20px)%20(1200%20x%20675%20px)%20(3600%20x%201600%20px)%20(1460%20x%20830%20px)%20(3600%20x%201600%20px)%20(1360%20x%20705%20px)%20(3600%20x%201600%20px)%20(900%20x%20700%20px)%20(3600%20x%201600%20px)%20(1360%20x%20705%20px)%20(1360%20x%20%20(23).jpg)

%20(1100%20x%20830%20px)%20(1200%20x%20675%20px)%20(3600%20x%201600%20px)%20(1460%20x%20830%20px)%20(3600%20x%201600%20px)%20(1360%20x%20705%20px)%20(3600%20x%201600%20px)%20(900%20x%20700%20px)%20(3600%20x%201600%20px)%20(1360%20x%20705%20px)%20(1360%20x%20%20(20).jpg?width=1460&height=830&name=Untitled%20(1460%20x%20830%20px)%20(1100%20x%20830%20px)%20(1200%20x%20675%20px)%20(3600%20x%201600%20px)%20(1460%20x%20830%20px)%20(3600%20x%201600%20px)%20(1360%20x%20705%20px)%20(3600%20x%201600%20px)%20(900%20x%20700%20px)%20(3600%20x%201600%20px)%20(1360%20x%20705%20px)%20(1360%20x%20%20(20).jpg)

ICCP-SAM Tool

Developed in response to growing market demand and in collaboration with CORROSION, the ICCP-SAM (Impressed Current Cathodic Protection - Subsea Assembly Method) tool is specifically designed to remotely install ICCP anodes on monopile foundations of all sizes, anywhere on the foundation and even in the roughest ocean conditions.

The latest upgrades to the ICCP-SAM focus on optimising both the installation process and the performance of the anode system, improving the reliability of the tool in challenging offshore subsea conditions.

Why OEG Renewables

We are progessive and pioneering business. Continued investment by OEG Renewables in the design and development of subsea tools and solutions demonstrates a commitment to pioneering innovation in the offshore renewables sector, providing sustainable and scalable solutions for a range of subsea challenges.

%20(1100%20x%20830%20px)%20(1200%20x%20675%20px)%20(3600%20x%201600%20px)%20(1460%20x%20830%20px)%20(3600%20x%201600%20px)%20(1360%20x%20705%20px)%20(3600%20x%201600%20px)%20(900%20x%20700%20px)%20(3600%20x%201600%20px)%20(1360%20x%20705%20px)%20(1360%20x%20%20(16).jpg?width=2000&name=Untitled%20(1460%20x%20830%20px)%20(1100%20x%20830%20px)%20(1200%20x%20675%20px)%20(3600%20x%201600%20px)%20(1460%20x%20830%20px)%20(3600%20x%201600%20px)%20(1360%20x%20705%20px)%20(3600%20x%201600%20px)%20(900%20x%20700%20px)%20(3600%20x%201600%20px)%20(1360%20x%20705%20px)%20(1360%20x%20%20(16).jpg)

%20(1460%20x%20830%20px)%20(1460%20x%20830%20px)%20(1920%20x%201080%20px)%20(1920%20x%201080%20px)%20(3600%20x%201600%20px)%20(1920%20x%201080%20px)%20(1920%20x%201080%20px)%20(1460%20x%20830%20px)%20(1920%20x%201080%20px).jpg)

%20(1460%20x%20830%20px)%20(1460%20x%20830%20px)%20(1920%20x%201080%20px)%20(1920%20x%201080%20px)%20(3600%20x%201600%20px)%20(1920%20x%201080%20px)%20(1920%20x%201080%20px)%20(1460%20x%20830%20px)%20(2).jpg)

%20(1100%20x%20830%20px)%20(1200%20x%20675%20px)%20(3600%20x%201600%20px)%20(1460%20x%20830%20px)%20(3600%20x%201600%20px)%20(1360%20x%20705%20px)%20(3600%20x%201600%20px)%20(900%20x%20700%20px)%20(3600%20x%201600%20px)%20(1360%20x%20705%20px)%20(1360%20x%20%20(13).jpg)