SEAJET, an OEG Renewables company, has successfully tested its revolutionary All-Electric Controlled Flow Excavation solution for the Offshore Sector.

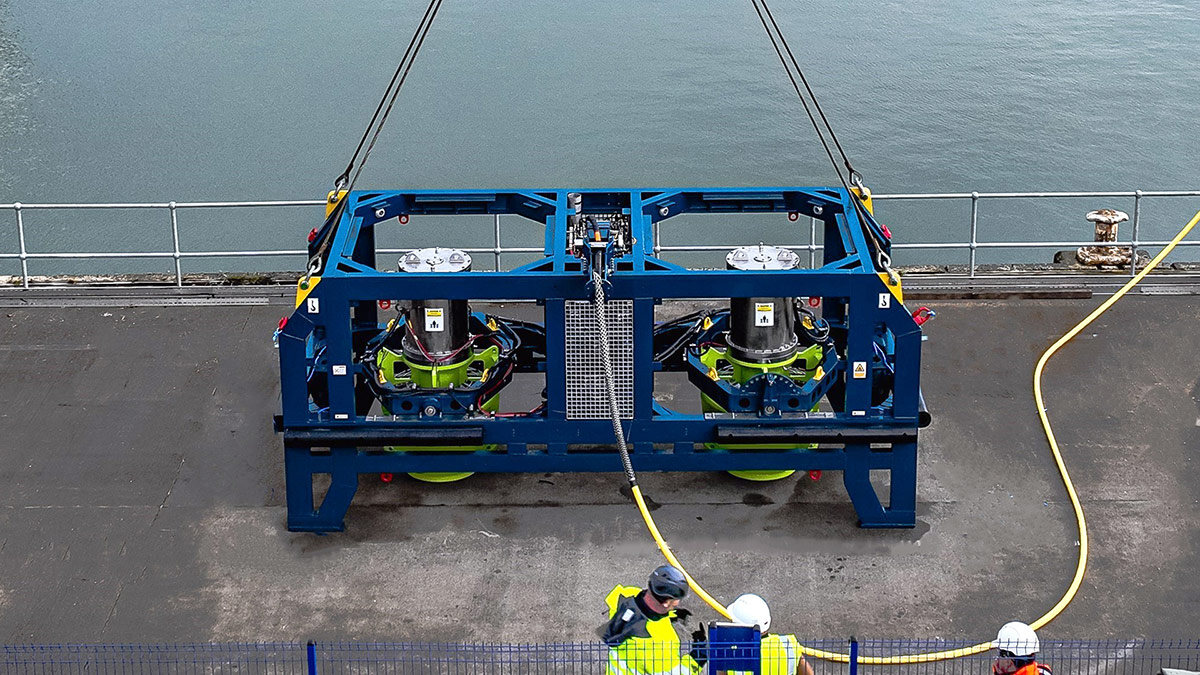

Wet testing of the All-Electric Controlled Flow Excavation (E-CFE®) technology called HYDROMOLE.

OEG Energy Group, a leading offshore solutions business, is pleased to announce that SEAJET an OEG Renewables company, has successfully wet tested its all-Electric Controlled Flow Excavation (“E-CFE®”) technology called HYDROMOLE. The ‘wet test’ was completed at ORE Catapult research centre in Blyth, Newcastle in the Northeast of England and represents the final milestone in the development of the world’s first all-electric twin CFE, which is now available for commercial deployment into the global subsea market.

This revolutionary HYDROMOLE E-CFE® system is the most powerful and advanced system available in the market with the ability to deliver 400kW of power to the seabed, independent of water depth. The advanced control system on the HYDROMOLE also allows system performance to be monitored and optimised in real-time, ensuring reliability and maximising project uptime. In departing from industry standard older hydraulic technology, E-CFE® also massively reduces CO2 emissions and fuel cost savings by 40% as well as eliminating the risk of high-pressure, high-volume oil spills into the marine environment.

The system has a wide range of applications across the full lifecycle of an offshore energy project, from pre-commissioning, construction, inspection, maintenance and repair through to final decommissioning. The non-contact method of excavation and trenching allows for multiple applications such as seabed preparation, cable and pipeline trenching and backfilling, free-span mitigation and the deburial of subsea infrastructure.

OEG’s multi-million-dollar investment, combined with SEAJET’s management team who have unrivalled experience in this sector, and a manufacturing partnership with Soil Machine Dynamics (“SMD”) have resulted in the development of a transformational technology for seabed intervention. Being part of OEG also allows access to a global infrastructure of offices and facilities giving SEAJET the capability to provide HYDROMOLE to clients in strategic locations around the world.

Testing SEAJET Hydromole

Highlights:

- With the success of the HYDROMOLE E-CFE® wet test, the world’s first all-electric CFE system is now available for commercial deployment. The system is 50% more powerful than existing hydraulic technology, is safer and cleaner and with no risk of pressurised oil leaks to the environment.

- The advanced subsea and topsides equipment have all been designed and manufactured in partnership with SMD in the UK, underlining OEG and SEAJET’s strong commitment to developing highly skilled green jobs for the benefit of the local economies in which it works.

- This UK designed and built technology has the potential to revolutionise the deployment of this kind of system by delivering an environmentally cleaner and safer system, with high performance and operational efficiency.

- The system represents a step change from the old hydraulic oil systems that deliver less reliable power, the need for more complicated and pressurised hydraulics and with the potential for oil leaks into the environment.

- SEAJET’s management team has unrivalled experience in the development and commercialisation of controlled flow excavation systems over the past 25 years having been involved in the execution of over 600 projects in more than 60 countries globally.

- OEG has designed and built the bespoke modules for SEAJET, this includes the Control Cabin, Power Cabin and Workshop Containers.

John Heiton, OEG’s Chief Executive Officer said:

Innovation is a core aspect of OEG’s business as we constantly seek to support our clients with more effective, reliable, and sustainable solutions. This is a first in its class development delivering a step-change in safety, environmental and operational performance underpinned by the best of British design and manufacturing. This multi-million investment into SEAJET, an OEG company, leverages the Group’s significant experience in offshore operations, working with major blue-chip clients, to deliver an innovative high-performance solution that lowers environmental impact and enhances our value proposition in the global subsea market.

Faisel Chaudry, Managing Director at SEAJET said:

We are delighted to have completed the significant final milestone of rigorous wet testing of SEAJET’s HYDROMOLE E-CFE® system. The open water trials have been a resounding success and have in fact exceeded the performance metrics we initially set out to achieve. The HYDROMOLE is now available to the global subsea market, with the fleet being expanded to meet demand across a wide range of offshore applications, in the UK and globally.